This product contains the following details

This product contains the following detailsCG1.6YC, CG2.5YC, CG4YC (Steel Case)Wireless remote transmission gas meters are type of new smart gas meter which is composed of flow signal acquisition module, wireless RF transmission module, IC card module, valve control module and power management module, with the diaphragm gas meter as a basic. The gas meter measures the flow rate of combustion gases like natural gas, liquefied petroleum gas (LPG), coal gas with the function of data conversion, wireless data transmission and valve control. The technical performance complies with GB/T 6968-2011 and JJG 577-2012.

The gas meters comply with GB3836.1-2010 Electrical apparatus for explosive gas atmospheres, Part 1: General requirements, and GB 3836.4-2010 Electrical apparatus for explosive gas atmospheres. Part 4: Intrinsic safety “i”. The gas meters’ ex-mark is ExibII BT3 Gb, and they are applicable to the place of II A-II B Zone 1 & Zone 2 and T1-T3 Explosive gas mixture. The gas meters are inspected and approved by Test Department:China National Quality Supervision and Test Centre for Explosion Protected Electrical Products (CQST) and obtained Ex Certificate of Conformity.

The torque of the table joint reaches over 250n.m, so as to better solve the sealing problem of the joint during installation.

Low static power consumption, long battery life;

The remaining information such as insufficient air volume, low battery pressure and valve status are displayed in Chinese, and the interface is intuitive.

Data access multiple encryption verification, safe and reliable;

Sensor fault automatic detection and fault treatment;

Abnormal information recording and data feedback function of gas meter;

The maximum allowable gas storage capacity can be set to avoid large amount of gas storage by users and reduce losses caused by gas price fluctuations in the gas management department.

Overdraft gas and alarm value can be set by users;

Maximum idle days of gas meters can be set;

The mask and module are treated with moisture-proof and oil-smoke prevention.

The management software adopts modular design, friendly man-machine interface, intuitive operation and easy to understand.

|

Technical data \ Type & specification |

CG1.6 |

CG2.5 |

CG4 |

|

|

Max. flow rate (m3/h) |

2.5 |

4 |

6 |

|

|

Min. flow rate (m3/h) |

0.016 |

0.025 |

0.04 |

|

|

Operating condition |

Relative humidity(%) |

≤85 |

||

|

Temp. (℃) |

-10~+40 |

|||

|

Max. operating pressure (kPa) |

20 |

|||

|

Total pressure loss (Pa) |

≤250 |

|||

|

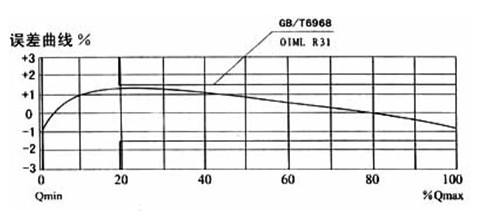

Error limit of reading(%) |

Accuracy class:1.5级 |

qmin≤q≤qt ±3 |

||

|

qt≤q≤qmax ±1.5 |

||||

|

Error limit of electromechanical signal conversion(m3) |

≤0.1 |

|||

|

Max. instantaneous current(mA) |

<200 |

|||

|

Quiescent operating current(uA) |

≤20 |

|||

|

Data storing time(year) |

>10 |

|||

|

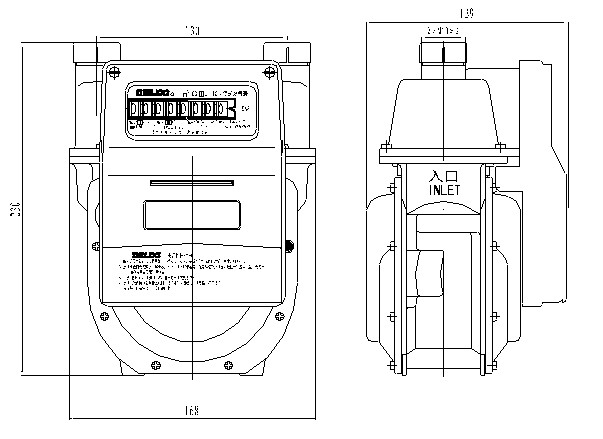

Center distance of pipe connector (mm) |

130 |

|||

|

Thread of pipe connector(mm) |

M30×2 |

|||

|

Outline dimension(mm) |

225×200×170 |

|||

|

weight(kg) |

2.2 |

|||

| IC卡使用次数(次) | >105 | |||

| 燃气体积基本显示单位(m3) | 0.1 | |||

| 最大瞬时电流(mA) | <160(阀门动作时) | |||

| 静态工作电流(uA) | <15 | |||

| 数据保持时间(年) | >10 | |||

| 电源6V | 4 1.5v alkaline no.5 batteries(LR6 1.5V) | |||

Error curve

□ It is suitable for installing at non-combustible structure and indoor place with good ventilation

□ It is prohibited to install at bedroom, bathroom and the place stored with dangerous goods and flammables, or somewhere similar to the aforesaid.

□ The installation of gas meter should satisfy the requirements of meter reading, repairing, maintenance and safety operation.

CHINESE

CHINESE

Print this page

Print this page Fav this page

Fav this page E-mail us: yqyb@delixi.com

E-mail us: yqyb@delixi.com